The Duty of Metal Casting beforehand Manufacturing Technologies

Metal Casting have notably influenced the development of producing innovations. They supply unique style flexibility, making it possible for the development of detailed geometries essential for numerous applications. Modern casting methods are being boosted by advancements like 3D printing and automation. These developments not just boost effectiveness but also address obstacles in accuracy and sustainability. As markets remain to evolve, the duty of Metal Casting stays important in shaping their future. What exists in advance in this vibrant area?

The Advancement of Steel Casting Strategies

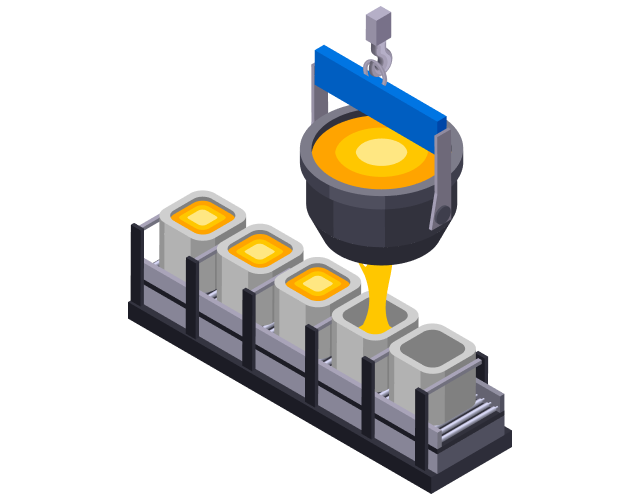

As the need for accuracy and effectiveness in manufacturing has grown, the advancement of Metal Casting strategies has undergone significant makeover. Historically, Metal Casting started with basic approaches such as sand casting and lost-wax casting, which enabled craftsmens to develop elaborate shapes. With time, improvements in technology introduced procedures like die spreading and financial investment spreading, boosting accuracy and decreasing waste. Aluminum Castings. The introduction of computer-aided style (CAD) and simulation software program changed the drawing board, allowing suppliers to anticipate possible issues and optimize designs before production. Additionally, the development of new materials, such as advanced alloys and compounds, has actually broadened the extent of applications for Metal Casting. Automation and robotics have further refined casting processes, improving uniformity and efficiency. Therefore, the Metal Casting sector has actually adapted to meet the needs of modern production, concentrating on sustainability and innovation to remain competitive in an ever-evolving marketplace

Applications of Metal Casting in Key Industries

The developments in Metal Casting strategies have actually opened a wide array of applications throughout numerous sectors. In the automobile market, Metal Casting are important for producing engine blocks, transmission real estates, and various other crucial elements that need high strength and toughness. The aerospace sector uses spreadings for elaborate parts like wind turbine blades and architectural components, making sure lightweight yet durable services for aircraft.

The construction market utilizes Metal Casting for structural aspects such as light beams and installations, contributing to the integrity of buildings and infrastructure. In the energy sector, castings play a critical duty in making elements for wind turbines and power generation equipment, boosting performance and dependability. Additionally, the medical field benefits from precision spreadings utilized in surgical instruments and prosthetics, showing the adaptability of Metal Casting throughout varied applications. This wide usage underscores the value of Metal Casting in modern production techniques.

Benefits of Metal Casting in Modern Manufacturing

Metal Casting supply countless benefits that substantially enhance modern manufacturing procedures. One vital benefit is style flexibility; Metal Casting permits for the production of intricate forms and intricate geometries that are impossible or typically difficult to achieve with other manufacturing approaches. This capacity makes it possible for manufacturers to enhance product layouts for performance and performance.

Additionally, Metal Casting can support a wide variety of materials, consisting of steel, light weight aluminum, and iron, which can be tailored to fulfill particular mechanical buildings and rust resistance requirements.

Cost-effectiveness is one more notable benefit; Metal Casting procedures can create huge amounts of parts with very little product waste, therefore reducing production costs.

The durability of actors metal parts adds to the durability of products, reducing the demand for constant substitutes. Overall, the advantages of Metal Casting significantly add to effectiveness, sustainability, and development within contemporary manufacturing settings.

Technologies Driving the Future of Metal Casting

While standard Metal Casting strategies have actually served the market well for years, current innovations are positioned to transform the area. Advancements such as 3D printing modern technology enable rapid prototyping and the production of intricate geometries that were previously unattainable. These advancements not only improve layout versatility but additionally minimize waste and shorten lead times. On top of that, the integration of automation and robotics in casting processes is enhancing operations, improving accuracy, and improving employee safety and security. Furthermore, the advancement of new alloys and composite materials is allowing the production of more powerful, lighter spreadings tailored for particular applications. Digital technologies, consisting of artificial intelligence and artificial intelligence, are maximizing spreading criteria and anticipating upkeep, driving improved top quality control. Collectively, these innovations are pushing the boundaries of Metal Casting, fostering greater effectiveness and sustainability in manufacturing, and placing the industry for future growth and competition.

Challenges and Solutions in Metal Casting Processes

As developments in Metal Casting technology proceed to reshape the industry, numerous obstacles stay that suppliers have to resolve to totally take advantage of these advancements. One considerable problem is the variability in material properties, which can lead to irregular top quality and performance. This irregularity frequently arises from changes in raw materials and processing conditions. Additionally, the climbing costs of energy and read review products present monetary constraints, pressing why not find out more suppliers to look for a lot more effective processes.

To battle these difficulties, companies are significantly taking on automated systems and progressed simulation strategies to enhance accuracy and uniformity. Implementing high quality control actions throughout the production procedure likewise assists in detecting issues early. Spending in research for alternate products may lower expenses and improve sustainability. By attending to these obstacles with cutting-edge solutions, the Metal Casting industry can boost performance and preserve competition in the developing production landscape.

Frequently Asked Concerns

What Materials Are Generally Utilized in Steel Casting Procedures?

Typical products used in Metal Casting procedures include aluminum, magnesium, bronze, and iron. Each product possesses one-of-a-kind residential properties that deal with various applications, improving the adaptability and performance of the last cast items in various sectors.

How Do Environmental Rules Effect Metal Casting Operations?

Ecological regulations oblige Metal Casting operations to embrace cleaner modern technologies and practices, typically boosting manufacturing costs. Compliance might result in innovative processes that decrease waste and exhausts, ultimately promoting sustainability within the Metal Casting industry.

What Are the Precaution in Metal Casting Facilities?

Precaution in Metal Casting facilities include proper ventilation, personal safety devices, regular safety and security training, devices upkeep, and adherence to security guidelines, ensuring a secure environment for employees while minimizing threats connected with unsafe products and processes.

Just How Is Quality Controlled in the Steel Casting Process?

Quality assurance in Metal Casting involves strenuous inspections, including visual assessments, dimensional checks, and product testing. Adherence to market criteria and carrying out top quality monitoring systems guarantees that castings meet given needs throughout the why not find out more production process.

What Is the Future Task Expectation for Metal Casting Professionals?

The future job overview for Metal Casting specialists appears appealing, driven by advancements in innovation and raising need across various industries (Aluminum Foundry). Growth in automation and sustainable techniques will likely develop brand-new opportunities in this industry

Historically, Metal Casting started with simple approaches such as sand spreading and lost-wax casting, which enabled artisans to create elaborate forms. Over time, improvements in technology introduced processes like die spreading and investment spreading, improving accuracy and minimizing waste. In enhancement, the clinical field benefits from precision castings made use of in surgical instruments and prosthetics, demonstrating the flexibility of Metal Casting throughout varied applications. Metal Casting use various advantages that greatly improve modern manufacturing processes. Typical materials used in Metal Casting procedures include aluminum, iron, magnesium, and bronze.